by tradesmeninsights | Sep 3, 2012 | Uncategorized

Happy Labor Day! We need to take time to say thanks to all the tradesmen that we come into contact with on a regular basis. What would we do without the electricians, plumbers, HVAC professionals? How would our factories run smoothly without all the MRO professionals out there?

Sonnhalter salutes America’s professional tradesmen and laborers on this very special holiday. Our working force built this country. And it’s because of each and every American’s labors that we enjoy the freedoms we have today.

At Sonnhalter, we earn our own living by marketing to professional tradesmen in industries like yours…from construction to industrial to MRO. To show our appreciation for such hard-working individuals, we offer a tip of the hardhat and our sincere thanks.

However you celebrate your Labor Day, enjoy it. You’ve certainly earned it.

by tradesmeninsights | Aug 28, 2012 | Uncategorized

Today we have a guest post from Derek Singleton from Software Advice, a company that helps companies pick the right software whether it’s for an application or industry. Derek has been a guest blogger before and it’s always good to get someone else’s insights. Enjoy.

Want a Construction Job? Get These Skills

In the construction industry, jobs are hard to come by. But a June report released by the Associated General Contractors of America (AGC) indicates that–at least in some states–it’s getting easier. In the report, the AGC finds that 20 states added new construction jobs.

According to AGC data, states with highest percentage of job gains are Montana and Wyoming which posted 12-month growth rates of 15.2 percent and 13.7 percent, respectively. At the opposite end of the spectrum are Alaska and Wisconsin with respective losses of 20 percent and 10.6 percent.

To find out what’s driving these job losses and gains, I recently caught up with AGC’s Chief Economist, Ken Simonson. In my conversation with Simonson, he highlighted three main drivers behind the current trends in construction employment:

- Low vacancy rates are spurring investment in apartment complex construction.

- The acceleration of natural gas extraction is fueling related construction job growth.

- Manufacturing investment is leading to new manufacturing facility construction.

So what kinds of jobs fit well with these market drivers? Below I’ll profile a few relevant professions currently in demand.

Apartment Complex Construction

Apartment construction requires nearly every kind of construction trade on the job. However, there are a few particular positions that are particularly high demand.

Carpenter: Naturally, carpenters are in high demand as more complexes are built and they’re needed for everything from framing to setting crown molding.

Millwork: The millwork trade is in high demand to produce the doors, crown moldings, window casings, etc. needed to finish an apartment.

Electrician: Electricians that are familiar with multi-family electrical wiring and know how to run standard power distribution to lighting and other outlets in apartments are needed to provide power to an apartment.

Natural Gas Extraction

The growth in natural gas extraction from underground shales is also supporting new construction jobs. The majority of these jobs involve heavy construction or civil engineering.

Earthwork and Excavation: The earthwork industry is needed on natural gas extraction for everything from mining the minerals that are used in extraction to clearing roadway to the drill site.

Civil Engineering: Of course, effectively planning these roadways requires civil engineers that can plan the infrastructure of these projects.

Manufacturing Facilities

Construction jobs are also being supported by the uptick in domestic manufacturing, which is prompting manufacturers to build new facilities in the U.S. As a result, there are two main professions that are in high demand.

Iron work: Iron work professionals are needed to put together the large steel frames that facilities require. Within the iron work profession, welders are among the most in demand professions as certified welders are hard to find given that it can take several years to achieve certification.

Electrician: Commercial electricians are needed when constructing a new manufacturing facility because of the need to install power and controls to motors and HVAC systems at the facility–in addition to the need to run power distribution directly from an electrical grid.

If you’re interested in learning more about how these jobs (and skills) fit into the trends I highlighted above, please stop by Software Advice to check out my original article and leave your thoughts here.

by tradesmeninsights | Aug 8, 2012 | Uncategorized

We subscribe to The Kiplinger Letter to keep abreast of the pulse of the markets and insights on what lies ahead. His observations and predictions of what’s ahead are usually right on.

In one of his recent newsletters he was talking about job creation and where the big need will be moving forward as the economy starts to pick up. According to Kiplinger, 85% of future jobs will come from six sectors, Health Care, Hospitality, Construction, Manufacturing, Business Services and Retail.

Among college degrees – science, math, engineering, technology and health sciences have the best prospects.

Among skilled workers – plumbers, electricians and HVAC mechanics can count on good demands. What’s interesting is that Kiplinger says that 25% of these folks (licensed skilled workers) will earn a bigger income than the average college graduate.

What are your thoughts?

You might be interested in these posts:

Here’s the Data: Why Manufacturing is the Right Career Choice

Why Aren’t Young People Considering Blue Collar Jobs?

Educating Tradesmen: What are you Doing to Play it Forward?

by tradesmeninsights | Jul 17, 2012 | Uncategorized

Guest Post

Miles Free, Technical Director of the Precision Machined Products Association (PMPA), has been a contributor before to this audience and he and I share the same enthusiasm about giving young people other options than a 4-year college degree. The association has been a great supporter of Right Skills Now that are local technical training programs that are very successful

Miles writes a blog for the association called Speaking of Precision. Miles sheds some current insights into the issue. Enjoy!

I remember the excitement of back to school when I was child – new clothes, new shoes, maybe a new notebook, and new school supplies. These items embodied my parents’ wishes for us to succeed academically and earn a better place in the world. Blue-collar budgets meant money was tight, and a well thought out list assured that they did the best for the family with the resources we had.

It is back to school time and while my children have long since left the nest, I have been thinking about what we, would as employers, put on this year’s back to school list for our shops and for our industry?

People that want to work. At a meeting in Chicago recently, I met a VP of Operations from a major soft drink company. What is number one on his list? He told me ‘people that want to work.’ Really. ‘I am looking for people looking for a job, not those just looking for a paycheck. I’m looking for solid people who can make a difference as they make a career.’ His company offers internships and a company development program, but his first task every week is to review his vacancies report. Add people who want to work to the list.

Looking for talent, not labor. U.S Productivity is high, and one consequence is that we need talented people, not just bodies in the ‘labor gang.’ U.S. productivity doubled from 2008 to 2009; then it doubled again in 2010 according to the Organization for Economic Cooperation and Development. The jobs that were cut in 2008 and 2009 tended to be the least skilled positions at any company, according to most press reports.

Now, companies seem to have hit the limit for what they can produce with the talent that they have. To make more sales, they need to add talent, not just bodies. Add talented people to the list.

Urgent need for craft workers. Much of the value add in our industry comes from the programming, set-up and operation of high-tech multiple axis CNC machines. This is not ‘just push the big green button’ work. An inefficient program can cost the company dollars per part if the program runs too slow. Setting up the machine in a longer time than that planned results in higher costs and lost profits. Operators have to be on top of their game to assure all features are produced to spec and that tools are replaced before they create problems. The craftsmen (and women!) in our precision machining industry add value by what they know and how they do.

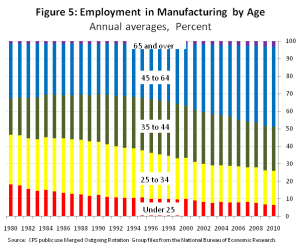

Our industry’s employees are getting closer to retirement. Median age (half the workforce is older, half is younger) was reported to be 51 for occupations in our industry according to BLS. According to Mark Doms, Chief Economist for the U.S. Department of Commerce, there is a “…longer-term trend of an increase in the average age of those employed in the manufacturing industry. Those age 45 years or older now comprise almost half of manufacturing employment, up from about one-third in the mid-to-late 1990s.” With 10,000 baby boomers turning age 65 each day, our industry – every industry – needs a plan to retain the knowledge and capture the skills of our departing workers.

Willing to train. My parents bought me my school supplies, knowing that I would take them to school. Given the need to replace our retiring highly productive craft workers, what has changed is that for employers at least, we are going to have to step up our investment in training, cross training, and setting up programs for knowledge retention and the capturing of ‘tribal knowledge.’ Unlike my parents, who bought me school supplies, packed my lunch, and sent me off to school, employers today need to take charge of the training and development of the people who add value in our shops. We can no longer take for granted that a surplus of craft machinists is ‘out there’ somewhere just waiting for our offer. We need to actively manage for today’s reality – High productivity, high technology workplaces require skilled, talented, trained employees. We can’t just take what the schools give us. We need to tell the schools what we are looking for in our hires.

Eliminate the skills gap. The policy wonks in Washington D.C., many state capitals, and on our TV ‘news programs’ can debate the finer points of whether or not the U.S. has a skills gap or a skills mismatch. Every employer that I have spoken with in the precision machining industry has told me that if they didn’t have an opening, they would create one for the right candidate if they applied at their shop. That fact alone tells me that the debate is irrelevant. U.S. advanced manufacturing companies must have a talented, trained cadre of capable workers in our industry specialties like CNC programming, Setup, and operation, if we are to remain competitive and sustain manufacturing as a competitive strength here in North America.

Like my folks who wanted to see their kids earn a better place in the world, our companies should be leaders in helping to improve the visibility, value and prestige of the advanced manufacturing people who make a difference in our shops each and every day. By applying their talent, skills and efforts, cars are safer, food and beverages are delivered hygienically, and aircraft and medical devices can be relied upon. As employers, we have a list of what we need. Our job now is to turn that list into a list of actions to make a difference.

The first item on that list should be “to increase the visibility, value and prestige of precision machinists, programmers, engineers and our other high value team members.” If we take this first step, we will make it possible to find people who want to work, people with talent, people able to be trained for our craft, so that we can eliminate the skills gap and keep our shops as competitive and sustainable centers of advanced manufacturing and productive value adding activity.

The longest journey starts with but a single step. Let’s take that first step to let the world know just how good a career awaits them in precision machining. We can, we must, sustain the competitiveness of our shops and industry through our back to school investment.

by tradesmeninsights | Jul 10, 2012 | Uncategorized

Recently, our President, Matt Sonnhalter, was part of a webinar and he’d like to share some highlights of what’s to come in regards to mobile. Enjoy.

I was recently a co-presenter for a B2B Mobile Marketing webinar sponsored by CFE Media. During the course of my research and prep for this webinar, I was overwhelmed by some of the mobile stats I came across…here are just a few:

– Mobile will be the “first screen” for all Web usage sometime between 2013-2015 (Gartner/Morgan Stanley) – which means mobile devices will finally overtake PCs

– 5.3 billion mobile subscriptions worldwide (ITU) – more than the combined penetration of PCs, landlines and TVs

– 50% of American adults own a smartphone as of February 2012 (CTIA)

– 29% of US adults own a tablet/eReader as of January 2012 (Pew Research Center)

There also continues to be tremendous growth in pretty much all aspects of mobile marketing tactics:

– Revenues from mobile apps will reach $46B by 2016 (ABI Research)

– Mobile video views increased 958% from Q2 2011 to Q1 2012 (Millennial Media Study)

– 20 million QR code scans were recorded alone in Q3 2011 – a 440% increases year-over-year (ScanLife)

– Almost 40 million US mobile users access social media sites daily (comScore)

So why is mobile relevant for B2B marketers trying to reach the professional tradesmen? Smartphones are an integral part of today’s professional tradesman toolbox. These guys are always “on the go;” on the job site and in the field…they need to be able to access information whenever and from wherever they want…these guys are not sitting behind a desk in front of a computer screen. And I’ve got news for you; if your company has a website…you are already playing in the mobile space! So how can you make sure your brand/company is represented well? Here are two simple steps to help get you started with mobile marketing:

1) Optimize for Mobile – make sure all of your Web content is “optimized” for the mobile environment; look-and-feel for smaller size requirements (e.g. easy to read text; no Flash; images that load quickly); but you also have to make sure your content is transformed into: quick answers, bite-sized units (e.g. 100-200 words) and easy-to-digest formats (e.g. audio podcasts and/or video)

2) Integrate – before you run out and develop a completely separate mobile marketing strategy and plan, take a look at your existing marketing programs and determine how you can start integrating mobile components; such as QR codes on print or collateral pieces or optimized e-newsletters so they are legible on mobile devices

I think it is fair to say that “mobile” is certainly here to stay, so make sure it is part of your overall marketing program moving forward.

Click image below to access the archived webinar.

If you like this post, you might want to read:

Reaching Contractors via Mobile. See What Grainger is Doing.

Are you Targeting Emails for Your Mobile Marketing?

Why a Mobile Strategy is so Important to Reach the Professional Tradesman

What’s your Mobile Media Strategy for 2012?

by tradesmeninsights | May 23, 2012 | Uncategorized

If you’re in manufacturing, I don’t have to tell you the kinds of pressure you feel on a daily basis.

Eric Willis follows my blog and is a manufacturer of fasteners in the UK. Eric works as a distribution manager at EJOT UK providing high tension custom fasteners to the aerospace and defense market. EJOT’s global distribution network makes it one of the largest fastener suppliers based in Europe.

He’d like to share his insights on how to stay ahead of the game.

How to Stay Ahead of the Game in the Fastener World

The volatile and unpredictable economy we live in today has wreaked havoc not only for consumers but also for businesses and offices in all markets and industries. The global recession has brought about certain impacts and effects that have rattled businesses to their knees and has made business stability seem like an utter dream.

In the fastener manufacturing market, the level of competition is high and continues to escalate in rampant proportions. It looks as if new manufacturers and suppliers of fasteners are established every day. Unfortunately, the rates of consumers and prospective buyers looking for these materials and supplies have not significantly increased throughout the course of time. This has made the level of competition fiercer than ever.

So what do you do? In the mind of a true businessman, staying ahead of competitors are of paramount concern, one that should be above all else in your list of priorities as a business executive or owner. Staying ahead of the game in the world of fastener manufacturing and distribution is something one cannot simply plan overnight even for the versed and experienced owner or director. To stay ahead and ensure that traffic flows come your way, meticulously planning and perfectly executing the plan is of key essence, and can make or break your business.

For people who know little or have no familiarity or knowledge at all regarding the market or industry of manufacturing fasteners, you won’t likely think of the difficulty owners face when competing with each other. Making sure your business is always competitively operating in multinational markets is also very difficult with lots of variables outside of your control. With the ubiquity of outsourcing and the access of global resources in today’s modern day and age, the manufacturing world is actually in a consistent struggle with rivals.

Here are 3 tips and guidelines on how you can add a competitive edge on your game in the vast and “dog-eat-dog” world of manufacturing, in this case manufacturing of fasteners.

First, lower the expenses of your business. In a simpler and more comprehensible context, if you can make the fasteners while consuming fewer funds for the same quality and quantity as compared with rivals, you’ll be able to provide more savings and discounts to your consumers and tilt the game to your advantage. Several of the most effective means of lowering expenditures involve tactics like outsourced manufacturing of the product, correctly forecasting to allow demand-based manufacturing, eliminating all delays in prefabricated parts and creating shared utilities. When provided with respective applicability to your facility, these techniques may yield a substantial benefit over competitors who opt not to play strategically.

Secondly, understand the standards and demands of your clients. Avoid leaving any worries or doubts in your customer’s mind when they opt to work with you in the future. Meet your client’s needs and demands by rendering them with the fastener supplies they need quicker and cheaper as compared with rivals.

Thirdly, find or create a unique selling point. These could be large brand awareness campaigns through supplying high-profile events such as F1 cars, Prototype Aeroplanes or Extreme engineering designs. Brand awareness in a saturated market can be the difference between stagnated growth and true development of a business.