by tradesmeninsights | Oct 15, 2013 | Uncategorized

I’ve discussed this in previous posts how there are other options besides a 4-year college degree and the debt that comes with it when choosing a career path. Today, discussing salary comparisons, we have a guest post from Miles Free, Director of Technology and Industry Research for PMPA (Precision Machined Products Association).

Many people think that the choice of where they went to school is an important factor in their post graduation earnings.

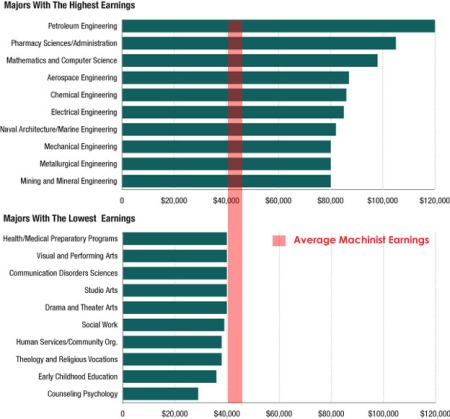

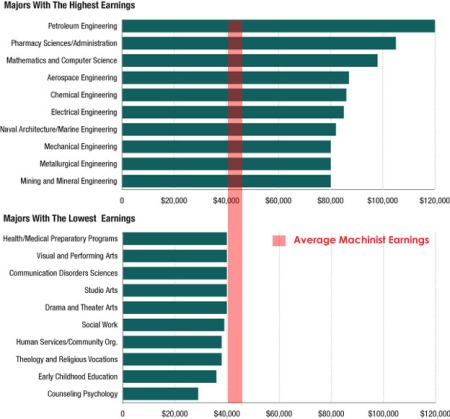

A report from Georgetown University shows that the choice of major has a much greater influence on those earnings.

We thought that we would show how the average wage of a skilled machinist compares to those earnings – without the 4+ years of college and the debt most graduates build up while at school.

Our figures for the skilled machinist were taken from our latest Shop Hourly Employee Wage Report and represent the annual straight time hourly earnings for a setup qualified multiple spindle, rotary transfer, Swiss type, or multi axis CNC turning/machining center operator.

The machinist earnings are a low estimate, frankly, because many machinists are scheduled overtime.

The college major earnings data was posted by Planet Money on the NPR site. It was originally prepared by the authors of the Georgetown study.

Average earnings of setup qualified precision machinists exceed those of lowest earning college majors – without the college loans to repay.

We were well served by our college degree, eventually. The problem was, when we graduated, we were making more in manufacturing than our degree would earn us in an entry level position in our field.

If you have the passion for academics and a 4+ year university program, that’s great.

But if you know that you really aren’t “scholarship” material, and you’d rather be doing exciting work than writing papers and piling up student debt, we think it will be worth your time to investigate a career in precision machining – or any other craft like electrician, mechatronics, welding, tool and die making, robotics…

Successful completion of high school math algebra, geometry, trig is all that is needed to be able to do the math for precision machining.

We’d love to help you start your well paying career.

More information:

Career overview

Career benefits

Career training

P.S. I interviewed a member CEO today: Their machinists averaged $50,000 last year, plus top-of-the-line medical, vacation, holidays, personal days, uniforms, plus company paid training and more…You should really give serious thought to gaining a skill rather than a degree.

by tradesmeninsights | Jul 17, 2012 | Uncategorized

Guest Post

Miles Free, Technical Director of the Precision Machined Products Association (PMPA), has been a contributor before to this audience and he and I share the same enthusiasm about giving young people other options than a 4-year college degree. The association has been a great supporter of Right Skills Now that are local technical training programs that are very successful

Miles writes a blog for the association called Speaking of Precision. Miles sheds some current insights into the issue. Enjoy!

I remember the excitement of back to school when I was child – new clothes, new shoes, maybe a new notebook, and new school supplies. These items embodied my parents’ wishes for us to succeed academically and earn a better place in the world. Blue-collar budgets meant money was tight, and a well thought out list assured that they did the best for the family with the resources we had.

It is back to school time and while my children have long since left the nest, I have been thinking about what we, would as employers, put on this year’s back to school list for our shops and for our industry?

People that want to work. At a meeting in Chicago recently, I met a VP of Operations from a major soft drink company. What is number one on his list? He told me ‘people that want to work.’ Really. ‘I am looking for people looking for a job, not those just looking for a paycheck. I’m looking for solid people who can make a difference as they make a career.’ His company offers internships and a company development program, but his first task every week is to review his vacancies report. Add people who want to work to the list.

Looking for talent, not labor. U.S Productivity is high, and one consequence is that we need talented people, not just bodies in the ‘labor gang.’ U.S. productivity doubled from 2008 to 2009; then it doubled again in 2010 according to the Organization for Economic Cooperation and Development. The jobs that were cut in 2008 and 2009 tended to be the least skilled positions at any company, according to most press reports.

Now, companies seem to have hit the limit for what they can produce with the talent that they have. To make more sales, they need to add talent, not just bodies. Add talented people to the list.

Urgent need for craft workers. Much of the value add in our industry comes from the programming, set-up and operation of high-tech multiple axis CNC machines. This is not ‘just push the big green button’ work. An inefficient program can cost the company dollars per part if the program runs too slow. Setting up the machine in a longer time than that planned results in higher costs and lost profits. Operators have to be on top of their game to assure all features are produced to spec and that tools are replaced before they create problems. The craftsmen (and women!) in our precision machining industry add value by what they know and how they do.

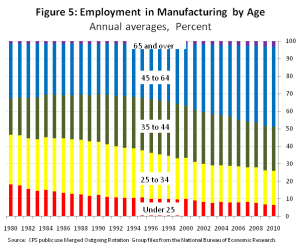

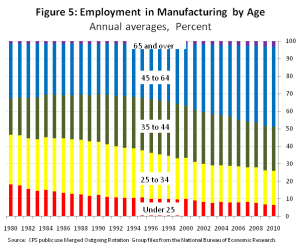

Our industry’s employees are getting closer to retirement. Median age (half the workforce is older, half is younger) was reported to be 51 for occupations in our industry according to BLS. According to Mark Doms, Chief Economist for the U.S. Department of Commerce, there is a “…longer-term trend of an increase in the average age of those employed in the manufacturing industry. Those age 45 years or older now comprise almost half of manufacturing employment, up from about one-third in the mid-to-late 1990s.” With 10,000 baby boomers turning age 65 each day, our industry – every industry – needs a plan to retain the knowledge and capture the skills of our departing workers.

Willing to train. My parents bought me my school supplies, knowing that I would take them to school. Given the need to replace our retiring highly productive craft workers, what has changed is that for employers at least, we are going to have to step up our investment in training, cross training, and setting up programs for knowledge retention and the capturing of ‘tribal knowledge.’ Unlike my parents, who bought me school supplies, packed my lunch, and sent me off to school, employers today need to take charge of the training and development of the people who add value in our shops. We can no longer take for granted that a surplus of craft machinists is ‘out there’ somewhere just waiting for our offer. We need to actively manage for today’s reality – High productivity, high technology workplaces require skilled, talented, trained employees. We can’t just take what the schools give us. We need to tell the schools what we are looking for in our hires.

Eliminate the skills gap. The policy wonks in Washington D.C., many state capitals, and on our TV ‘news programs’ can debate the finer points of whether or not the U.S. has a skills gap or a skills mismatch. Every employer that I have spoken with in the precision machining industry has told me that if they didn’t have an opening, they would create one for the right candidate if they applied at their shop. That fact alone tells me that the debate is irrelevant. U.S. advanced manufacturing companies must have a talented, trained cadre of capable workers in our industry specialties like CNC programming, Setup, and operation, if we are to remain competitive and sustain manufacturing as a competitive strength here in North America.

Like my folks who wanted to see their kids earn a better place in the world, our companies should be leaders in helping to improve the visibility, value and prestige of the advanced manufacturing people who make a difference in our shops each and every day. By applying their talent, skills and efforts, cars are safer, food and beverages are delivered hygienically, and aircraft and medical devices can be relied upon. As employers, we have a list of what we need. Our job now is to turn that list into a list of actions to make a difference.

The first item on that list should be “to increase the visibility, value and prestige of precision machinists, programmers, engineers and our other high value team members.” If we take this first step, we will make it possible to find people who want to work, people with talent, people able to be trained for our craft, so that we can eliminate the skills gap and keep our shops as competitive and sustainable centers of advanced manufacturing and productive value adding activity.

The longest journey starts with but a single step. Let’s take that first step to let the world know just how good a career awaits them in precision machining. We can, we must, sustain the competitiveness of our shops and industry through our back to school investment.

by tradesmeninsights | May 16, 2012 | Uncategorized

I’ve always been a big supporter of promoting manufacturing and tradesmen jobs. I recently came across a post from a client of ours, PMPA (Precision Machined Products Association). Miles Free, their Director of Industry Research and Technology, writes their blog, Speaking of Precision and I wanted to share his post.

Is now the right time for you to start your career in U.S. Manufacturing?

The phrase “get in on the ground floor” comes to mind…

I found this chart on Global Macro Monitor Blog on WordPress. They look at it for their purposes. Let’s look at it for ours.

I started my manufacturing career in September 1973, near the bottom of the “Nixon Decline.” It wasn’t easy – I had plenty of layoffs – but there was plenty of upside and I went from laborer in a sintering plant through a series of jobs to become, senior plant metallurgist, quality director, plant manager, division director for quality and technology.

Being in the right place at the right time (manufacturing) from 1973 to 1977 allowed me to take advantage of the upside in manufacturing that gave me the momentum to grow my career.

Looking at the chart above, 2012 looks like the exact same opportunity, only better.

Global Macro Monitor lists some of the factors which influenced the chart above:

- Strengthening of the dollar during the 1980′s;

- Globalization;

- Entry of China and India into the global labor force;

- The internet;

- Improved productivity;

- Technological innovation;

- Demographics and worker preferences;

- All of the above.

I speak and meet with precision machining company managers and owners daily.

All are looking for people with skills and talent.

All are investing in training for their proven performers.

Our National Technical Conference last week had over 102 first time attendees.

Twice as many companies offered internships as there were students in our first Right Skills Now class.

A comment I received yesterday on Linked In: “I teach Precision Machining and our students are all getting jobs now and the starting pay is getting better… ”

These are some very strong indicators that now is a great time to start a career in manufacturing.

If you can do the math and solve problems based on your experiences, we’d love to have you in our precision machining industry.

P.S. And even though I characterized it as the “Nixon Decline,” I am not at all holding any president responsible for these.

There are far more important factors at play in this chart than whether or not there is a Donkey or an Elephant in the oval office.

by tradesmeninsights | Feb 25, 2010 | Marketing Tips, Social Marketing

Trade associations, by design, are supposed to be the “official spokesperson” for their constituency. Most though have missed the opportunity to harness the power of the Internet and social media. This is especially true of the more conservative manufacturing-type groups.

Trade associations, by design, are supposed to be the “official spokesperson” for their constituency. Most though have missed the opportunity to harness the power of the Internet and social media. This is especially true of the more conservative manufacturing-type groups.

One such group that has done a great job in using the Internet and the social media tools is The Precision Machined Products Association (PMPA). They have a blog (Speaking of Precision) and are active on LinkedIn, Facebook and Twitter.

Miles Free, Director of Technology and Industry Research (also Chief Blogger) says: “Our members value the PMPA for the ability to network. Using our blog to provide thought leadership, technical resources, advocacy, another channel for communication, and recruitment helps us help our members and the industry stay connected. We use social media to help us provide connection, effective advocacy, and keep our members and the industry apprised of critical issues. At virtually no cost. For PMPA, social media is key to effective associating.”

Here are 5 reasons they are using social media :

- Thought leadership – They want to be known as the “Experts” in their space and their blog.

- Technical resource – To keep the industry updated on issues ranging from the latest OSHA requirements to new specs for a certain quality program, as well as to promote knowledge retention.

- Advocacy – All associations need representation in Government whether it’s national, state or local. Their position on issues are vital and social is a great place to rally the troops.

- Communicate with members – Most associations have several ways to touch their members, but blogs let them focus on one key subject and communicate with them on a regular basis, but in a different format that they are used to.

- Recruitment tool for new members – All associations are looking for new members, and this is a way for new potentials to see what they are doing and identify themselves as potential new members.

So, if you belong to an association and they aren’t using social media, tell them they are missing a great opportunity.