by tradesmeninsights | Feb 3, 2016 | Uncategorized

By Miles Free of PMPA. This post originally appears on pmpaspeakingofprecision.com and is reposted with permission.

Today our growth is limited by our inability to acquire skilled workers. In the last recession, we were held back by lack of demand for our customer’s end products. Today, we cannot find the skilled people that we require to operate new high tech equipment that is needed to make the high precision parts we produce.

Our shops are tackling this issue in a number of ways. Some are setting up internal training programs, some apprenticeships. Several of our member companies are creating on-site schools to teach skills needed. As an industry we helped to create, and are supporting initiatives like Right Skills Now. Right Skills Now uses National Institute for Metalworking Skills (NIMS) credentials to create the skilled workforce that manufacturers require to remain competitive in today’s global markets.

Claim: The President had this to say about employment and manufacturing:

“More than 14 million new jobs; the strongest two years of job growth since the ’90s; an unemployment rate cut in half. Our auto industry just had its best year ever. Manufacturing has created nearly 900,000 new jobs in the past six years. And we’ve done all this while cutting our deficits by almost three-quarters. We’ve launched next-generation manufacturing hubs, and online tools that give an entrepreneur everything he or she needs to start a business in a single day.”

Response: We haven’t won this one yet.

“…there has been a gain of 878,000 jobs since February 2010. But Bureau of Labor Statistics data show that the number of manufacturing jobs is still 230,000 fewer than…in the depths of the recession — and 1.4 million fewer than when the recession began in December 2007. Indeed, the United States only gained 30,000 manufacturing jobs in all of 2015.” – Washington Post

Question: Why do we have a skilled workforce shortage when we are at the lowest labor participation rate in ten years?

Work yet to be done on unemployment

Regulatory Hostility (more…)

by tradesmeninsights | May 30, 2013 | Marketing Tips, Social Marketing

Mile Free, Director of Industry Research and Technology for the Precision Machined Products Association, is posting today with advice for connecting on social media. Miles blogs regularly on PMPA’s blog, Speaking of Precision.

As tradesmen, advertising used to be pretty easy to figure out. A yellow pages ad in the local phone book, small display advertisements in the newspaper and maybe some classified advertisements in the weekly as well. Near a big city? Maybe you would have bit the bullet for a display ad in their yellow pages too. As a customer, in the old days, that’s how I would have found you…

So who uses a phone book these days?

Who still has a land line phone?

How many folks with smartphones walk around carrying a phone book?

My latest phone book is still on the front porch

That’s a trick question. While no one is carrying a phone book, the fact is that when they need to find something, they go search for it. On their smart phone or web device. How easy are you to find on search? For what kind of things are you on Google’s page one?

I’m not suggesting that you need to pay for advertisements on Google to get to page one, but if you use social media tools correctly, you can be found on Google for the services that you provide, and that your customers want.

While I am a staff director for a trade association of precision machining companies, the lessons I learned about how to increase visibility in online search are just as applicable to tradesmen to build your credibility, and thus your visibility online.

Here are 5 steps to increasing your online visibility:

- Make sure that your website covers the products and services that you provide. Having an up-to-date website with photos is key to engaging your potential customers and audience. Think of it as your online showroom. Make it look like a showroom, a place where people would like to shop. Nice photos on your website and in your blog get you found on Google too.

- Create a blog to share your expertise. It will only take an hour or two a week to create some modest posts about your specialty, or show pictures and discuss a job you just completed, or why you should use a professional to do ____. Share it on both your business and personal Facebook pages.

- Use LinkedIn Groups and Facebook to increase your credibility in Google and other search engines. LinkedIn Groups are where you can post your blog posts as news items to get wider viewership. As Google finds your content on places other than your blog and website, it boosts your trust factor and credibility. Find them for your trade, your customers and your locale. Facebook provides a great way to have a conversation with your “natural market”- the folks you already know- and gives them material to help generate word of mouth. Even Twitter can have a role in your tradesman marketing.

- Repurpose what you already have. If you already have a sales brochure, repost sections of it as stand-alone blog content. Take photos from your jobs completed book, repost them telling a bit about the back story- How by doing it with your approach, you saved the owner $XXX in time or dollars. Or why these materials instead of XYZ…

- Share your expertise. Keeping your expertise hidden doesn’t help anyone. “3 things that can go wrong when you pour Liquid Fire ™ down your toilets instead of getting professional help” may just save someone’s eyesight, as well as help people think about what is really important when trying to solve their problem.

You are an expert. You don’t have to tell anyone why you use 1-1/4” fasteners instead of the 1” ones …but what’s the harm in pointing out that as a professional you use the right fastener for the job, as opposed to just buying the cheapest ones down at the depot store? And then showing them a photo of a job you had to fix because the other guy didn’t use the right fastener?

As you share more and more of your wisdom and experience online, if you tag it properly, you will soon discover that Google has put you on page one for some of products and services in your area that you offer. Because you blogged about them with credibility. And it happened without an ad buy- because to Google, you have become the credible expert in your area.

by tradesmeninsights | Jul 17, 2012 | Uncategorized

Guest Post

Miles Free, Technical Director of the Precision Machined Products Association (PMPA), has been a contributor before to this audience and he and I share the same enthusiasm about giving young people other options than a 4-year college degree. The association has been a great supporter of Right Skills Now that are local technical training programs that are very successful

Miles writes a blog for the association called Speaking of Precision. Miles sheds some current insights into the issue. Enjoy!

I remember the excitement of back to school when I was child – new clothes, new shoes, maybe a new notebook, and new school supplies. These items embodied my parents’ wishes for us to succeed academically and earn a better place in the world. Blue-collar budgets meant money was tight, and a well thought out list assured that they did the best for the family with the resources we had.

It is back to school time and while my children have long since left the nest, I have been thinking about what we, would as employers, put on this year’s back to school list for our shops and for our industry?

People that want to work. At a meeting in Chicago recently, I met a VP of Operations from a major soft drink company. What is number one on his list? He told me ‘people that want to work.’ Really. ‘I am looking for people looking for a job, not those just looking for a paycheck. I’m looking for solid people who can make a difference as they make a career.’ His company offers internships and a company development program, but his first task every week is to review his vacancies report. Add people who want to work to the list.

Looking for talent, not labor. U.S Productivity is high, and one consequence is that we need talented people, not just bodies in the ‘labor gang.’ U.S. productivity doubled from 2008 to 2009; then it doubled again in 2010 according to the Organization for Economic Cooperation and Development. The jobs that were cut in 2008 and 2009 tended to be the least skilled positions at any company, according to most press reports.

Now, companies seem to have hit the limit for what they can produce with the talent that they have. To make more sales, they need to add talent, not just bodies. Add talented people to the list.

Urgent need for craft workers. Much of the value add in our industry comes from the programming, set-up and operation of high-tech multiple axis CNC machines. This is not ‘just push the big green button’ work. An inefficient program can cost the company dollars per part if the program runs too slow. Setting up the machine in a longer time than that planned results in higher costs and lost profits. Operators have to be on top of their game to assure all features are produced to spec and that tools are replaced before they create problems. The craftsmen (and women!) in our precision machining industry add value by what they know and how they do.

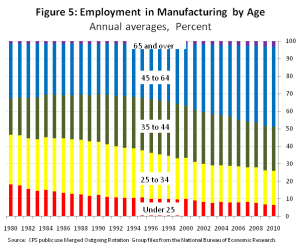

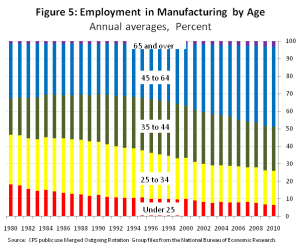

Our industry’s employees are getting closer to retirement. Median age (half the workforce is older, half is younger) was reported to be 51 for occupations in our industry according to BLS. According to Mark Doms, Chief Economist for the U.S. Department of Commerce, there is a “…longer-term trend of an increase in the average age of those employed in the manufacturing industry. Those age 45 years or older now comprise almost half of manufacturing employment, up from about one-third in the mid-to-late 1990s.” With 10,000 baby boomers turning age 65 each day, our industry – every industry – needs a plan to retain the knowledge and capture the skills of our departing workers.

Willing to train. My parents bought me my school supplies, knowing that I would take them to school. Given the need to replace our retiring highly productive craft workers, what has changed is that for employers at least, we are going to have to step up our investment in training, cross training, and setting up programs for knowledge retention and the capturing of ‘tribal knowledge.’ Unlike my parents, who bought me school supplies, packed my lunch, and sent me off to school, employers today need to take charge of the training and development of the people who add value in our shops. We can no longer take for granted that a surplus of craft machinists is ‘out there’ somewhere just waiting for our offer. We need to actively manage for today’s reality – High productivity, high technology workplaces require skilled, talented, trained employees. We can’t just take what the schools give us. We need to tell the schools what we are looking for in our hires.

Eliminate the skills gap. The policy wonks in Washington D.C., many state capitals, and on our TV ‘news programs’ can debate the finer points of whether or not the U.S. has a skills gap or a skills mismatch. Every employer that I have spoken with in the precision machining industry has told me that if they didn’t have an opening, they would create one for the right candidate if they applied at their shop. That fact alone tells me that the debate is irrelevant. U.S. advanced manufacturing companies must have a talented, trained cadre of capable workers in our industry specialties like CNC programming, Setup, and operation, if we are to remain competitive and sustain manufacturing as a competitive strength here in North America.

Like my folks who wanted to see their kids earn a better place in the world, our companies should be leaders in helping to improve the visibility, value and prestige of the advanced manufacturing people who make a difference in our shops each and every day. By applying their talent, skills and efforts, cars are safer, food and beverages are delivered hygienically, and aircraft and medical devices can be relied upon. As employers, we have a list of what we need. Our job now is to turn that list into a list of actions to make a difference.

The first item on that list should be “to increase the visibility, value and prestige of precision machinists, programmers, engineers and our other high value team members.” If we take this first step, we will make it possible to find people who want to work, people with talent, people able to be trained for our craft, so that we can eliminate the skills gap and keep our shops as competitive and sustainable centers of advanced manufacturing and productive value adding activity.

The longest journey starts with but a single step. Let’s take that first step to let the world know just how good a career awaits them in precision machining. We can, we must, sustain the competitiveness of our shops and industry through our back to school investment.

by tradesmeninsights | Jul 28, 2010 | Marketing Tips, Social Marketing

I’ve been talking about the benefits of social media in the B-to-B space now for almost 18 months and yet there are some companies out there that still don’t “get it.”

I wanted to share a success story with you of a traditional trade association, the PMPA (Precision Machined Products Association) and their results from starting a social program a little over a year ago (disclosure: they are a client of ours). These types of associations aren’t very sexy and they have plenty of competition out there for members to help them run their business better.

To better position themselves within the metalworking world as a thought leader and as part of a new business strategy, we recommended they jump on the social media bandwagon.

They did, and the following is an article written by Miles Free (Director of Industry Research and Technology, and principal contributor to their blog, Speaking of Precision) in their monthly magazine to members and potentials advocating they too jump on the social media bus.

PMPA content has been before people who are interested in it over 1,500,000 times in just one year at next to no out-of-pocket cost…

In just one year, we can document over 65,000 page views on PMPA’s Blog, SPEAKINGOFPRECISION.COM.

We’ve used Twitter to help connect people to our Blog content, and we’ve made hundreds of thousands of contacts using that tool. Once a week, one of our selected Blog topics gets uploaded to LinkedIn, where it is seen and shared by over 25,000 people in the machining, medical defense, and aerospace markets that belong to groups on LinkedIn. We can conservatively say that PMPA content has been before people who are interested in it over 1,500,000 times since we started our social networking program a year ago.

And on our blog we’ve posted some pretty good content – our posts on austenitic grain size, welding resulfurized steels, bar straightness, temper color, and material impacts – these all come up on page 1 of Google search results. Often in the top handful of non-paid links.

Page one on Google is the gold standard for information in the information age of today.

These social networking tools have helped us connect with members, potential members, your potential customers, suppliers, and the larger market for Precision Machining. The out-of-pocket expense was very small, trivial really. And the staff time required once we set it up is just a few hours a week.

So why haven’t you picked up these Social Networking Tools You Can Use? We’ve demonstrated that they can create connection, start a conversation, and introduce us to new clientele. Our getting topical page one rankings on Google shows that the knowledge that your shop has is just as likely to command attention in the Marketplace of Ideas online. Certainly you have special capabilities and expertise that when properly shared and targeted can help those people (and companies) who need and want to find you, to connect.

For several years, we’ve been working on the idea of connecting. Our member surveys always show Networking as a highly valued PMPA deliverable. Networking is done by connecting.

We’ve just had a one-year demonstration of what social media tools can do for an industry association. The numbers are as impressive as the costs are low. We hope that you will follow our experience by using these new tools to connect with tomorrow’s buyers who haven’t yet figured out that you can help them, and won’t take your salesman’s call if he finds them.

Social Media tools make you bigger in your market. The 30,000 people who see a message from us weekly are larger than the few thousands of people who were already in the PMPA “tent.” And they have conversations and network with people with similar wants and needs. Of course you want to reach them!

Consider social networking. Not just an email blats of a newsletter. A blog perhaps or enhancements to your website. At the very least, you need to be on LinkedIn. Join relevant groups. CUSTOMER GROUPS. Industry groups, any group that might conceivably be related to your business. Develop content. Share it weekly with your new Network. Do it now.

From PMPA’s first-year experience, there may be a million and a half or so of your potential followers, customers, and maybe even potential employees out there waiting to find you. And, perhaps, 60,000 or so opportunities to teach those who are really interested in what you might have to say – the stuff that makes you an expert and that they really need to know.

Social networking. It’s not about selling. It’s about cultivating your market. Connecting. Establishing your expertise. Finding your voice. Being found. Connecting.

Social Networking – it’s Tools You Can Use. Pick your tool. Give it a try.